OVERVIEWS

Gabions are rectangular wire mesh baskets filled with rock at the project site to form flexible, permeable, monolithic structures such as retaining walls for commercial, industrial and road projects. They are also used for erosion control, bank stabilization, channel linings, and wires.

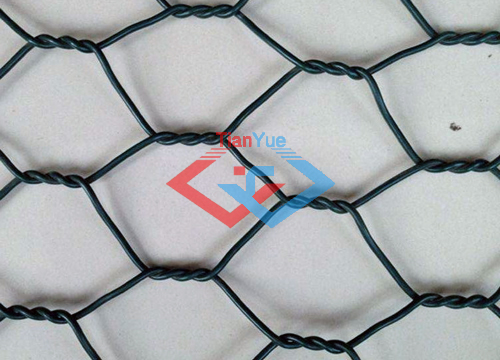

Gabion strength comes from a double twisted hexagonal mesh of steel wire which is reinforced by selvedges of heavier wire running along the edges and by transverse diaphragms. The double twisted wire will not unravel, even when cut.

Our gabions are very easy to assemble require no specialized labor and nearby rock can be used for fill. They are available with different levels of protective coating for durability. With 30% voids gabion structures offer free drainage providing higher bank stability when used for river bank protection.

All tests on wire must be performed prior to manufacturing the mesh. All wire should comply with ASTM A975-97; style 3 Coating, Gal fan and PVC coated steel wire. Wire used for the manufacture of gabions and the lacing wire, shall have a Maximum tensile strength of 75 000 psi (515 MPA) as per ASTM A856-03, soft temper steel.

SURFACE TREATMENT

• Heavily zinc galvanized wire

• As above plus heavy duty PVC coating

• Gal fan coated with a 95%Zinc + 5% Aluminum Mischmetal Alloy

• As above plus heavy duty PVC coating

FEATURES

• Gal fan coated with Zn-5%Al or Zn-10%Al, to compare to common galv. Gabion, it has more higher resistant to corrosion and about 2-3 higher than common.

SERVICE HOTLINE

Whatsapp/Wechat:+86 13623289181

Email: ty1@dianhanwang.com